Software for Aerospace Structural Analysis, Design Optimization, and Vehicle Lightweighting

Thank You to everyone who attended!

Collier Aerospace’s HyperX Users Conference 2025

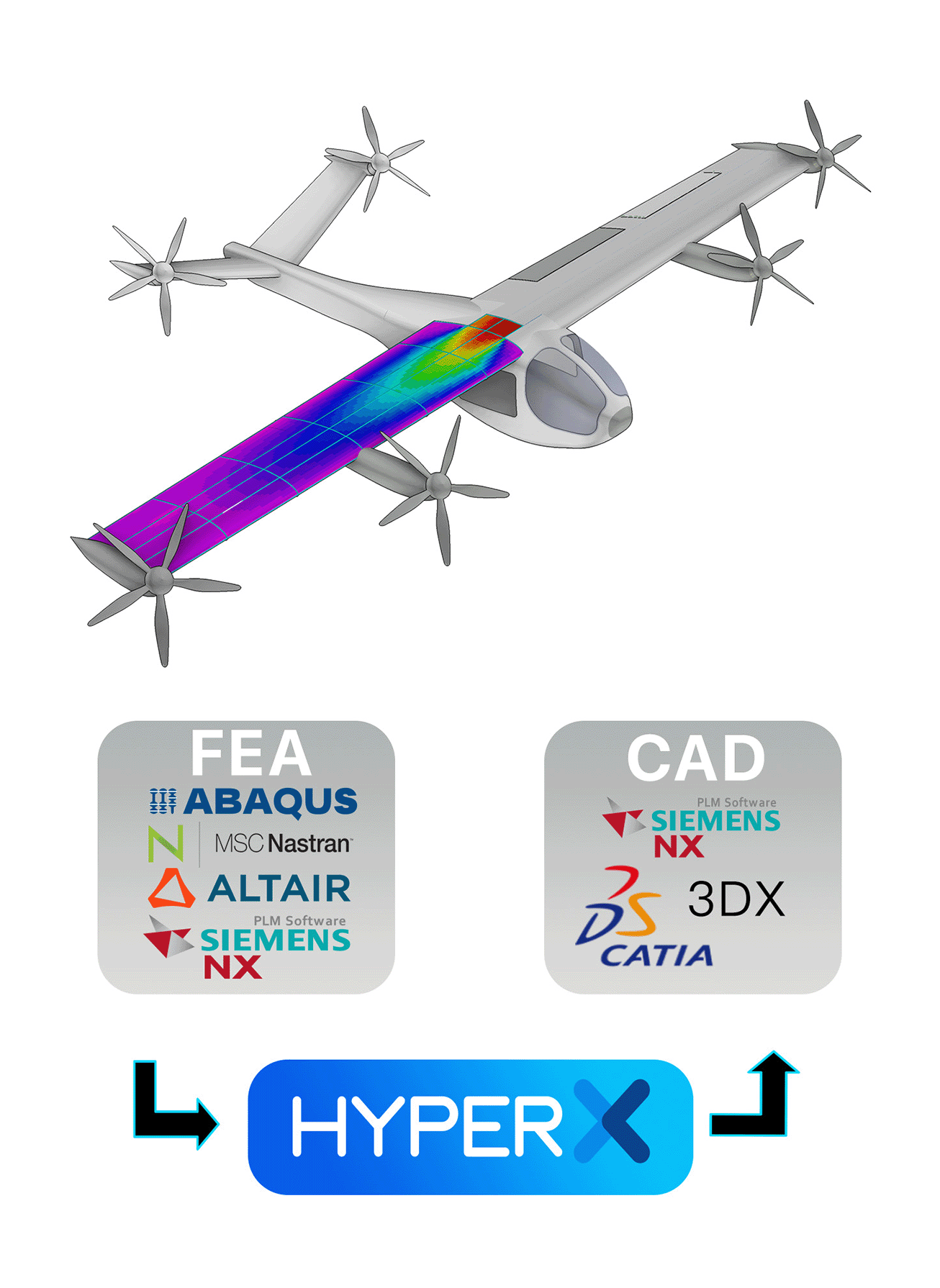

HyperX software provides engineers an automated framework to perform classical, industry standard aerospace failure analyses with margin-of-safety reporting for metal and composite airframes. Using these analyses, HyperX seamlessly performs structural sizing to minimize weight for the lightest manufacturable design of: laminates, ply shapes, sandwich panels, composite stiffened panels, metal machined grid-stiffened panels; fastened and bonded joints.

What is HyperX?

HyperX is a companion to your finite element solver for performing rapid closed form and detailed stress analysis for hundreds of analytical failure methods to thousands of FEA load cases. Using these analyses, HyperX performs sizing optimization to determine the lightest weight combination of material systems and panel cross-sectional dimensions (height, stiffener spacing) including layup ply angles and stacking sequences.

The HyperX workflow, analyses, and generated designs are agnostic to your preferred FEA and CAD products. As such, resulting panel and joint sized designs are automatically updated in both your FEM and CAD models, fully connecting the digital thread.

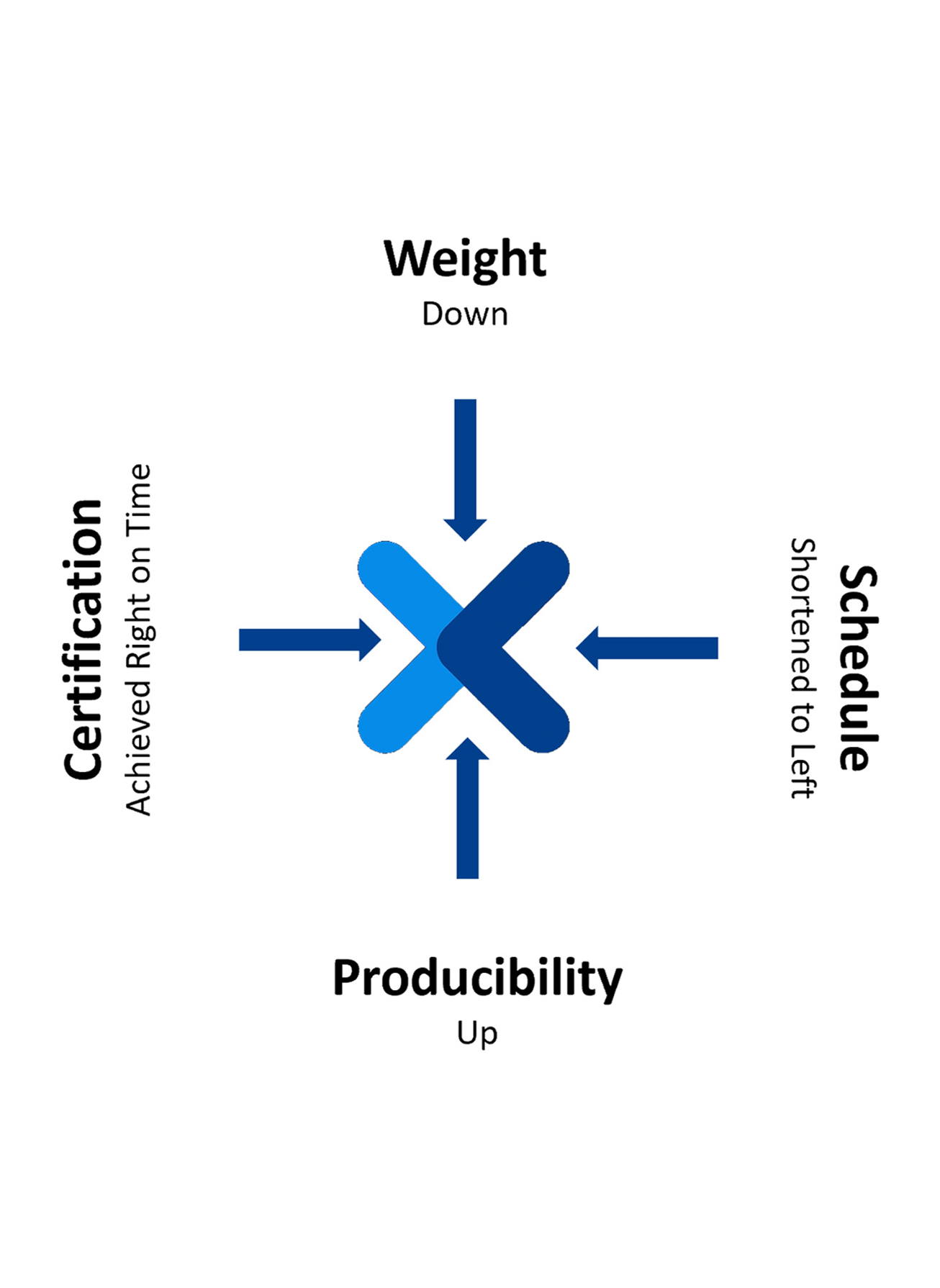

Why use HyperX?

To enable structural analysis and design teams to reduce weight, shorten development schedules, improve producibility and expedite the airframe certification process for composite & metal structures.

As a stress framework, the software standardizes your analysis and design process. Your company legacy methods can easily be customized into HyperX using its analysis plugin and API technology. For both HyperX native methods and your plugged-in methods, the software provides powerful interactive data traceability and generates Excel and Word stress reports along with equations and margin summaries. HyperX gets your engineering work done faster and consistently.

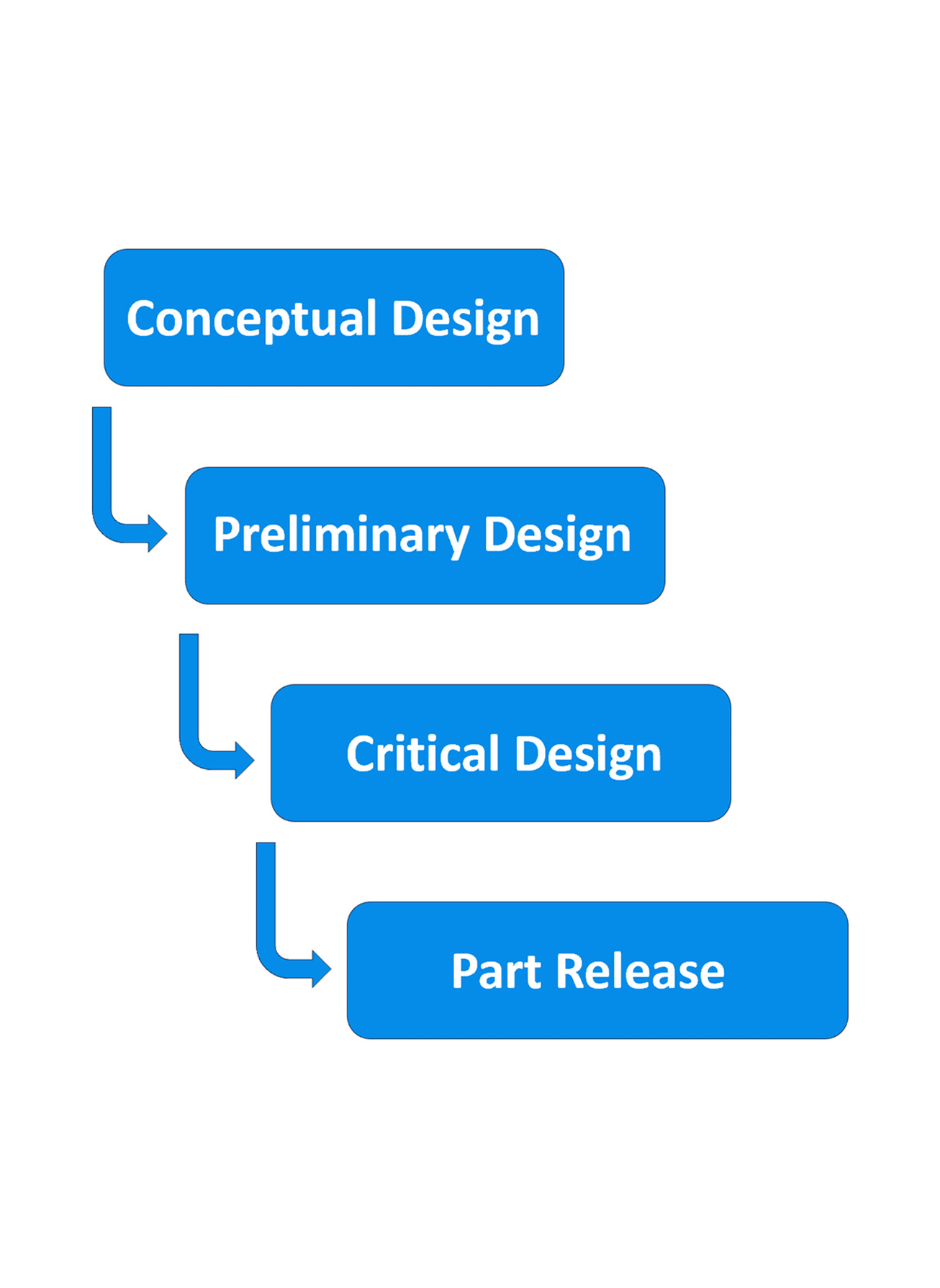

When to use HyperX?

The earlier the better… because HyperX provides “one source of truth” consistency from conceptual design all the way to final analysis certification. HyperX ensures that consistent data is used from project start to end with its database that contains your project’s material systems, laminate families, fastener vendor data, analysis policies, and design rules. The benefit is that you can avoid unexpected problems and weight growth as the design matures.

There are many capabilities specifically provided for each design phase: from conceptual to preliminary design review (PDR), all the way to critical design review (CDR) and part release.

Where is HyperX used?

HyperX software is used by individual engineers or by entire engineering departments following the enterprise workflow with shared databases. Users come from industry (large OEMs and startups) and government (NASA and the Air Force Research Lab), as well as universities.

Applications include Space launch vehicles, reusable rockets, (specializing in fairings, pressurized fuel tanks, intertanks, thrust structures, and fins); commercial airframes, business jets, and eVTOLs in the UAM and AAM markets (specializing in fuselage, wing, and empennage structures); and high-performance composites such as bike frames, Formula 1, and speed boats.

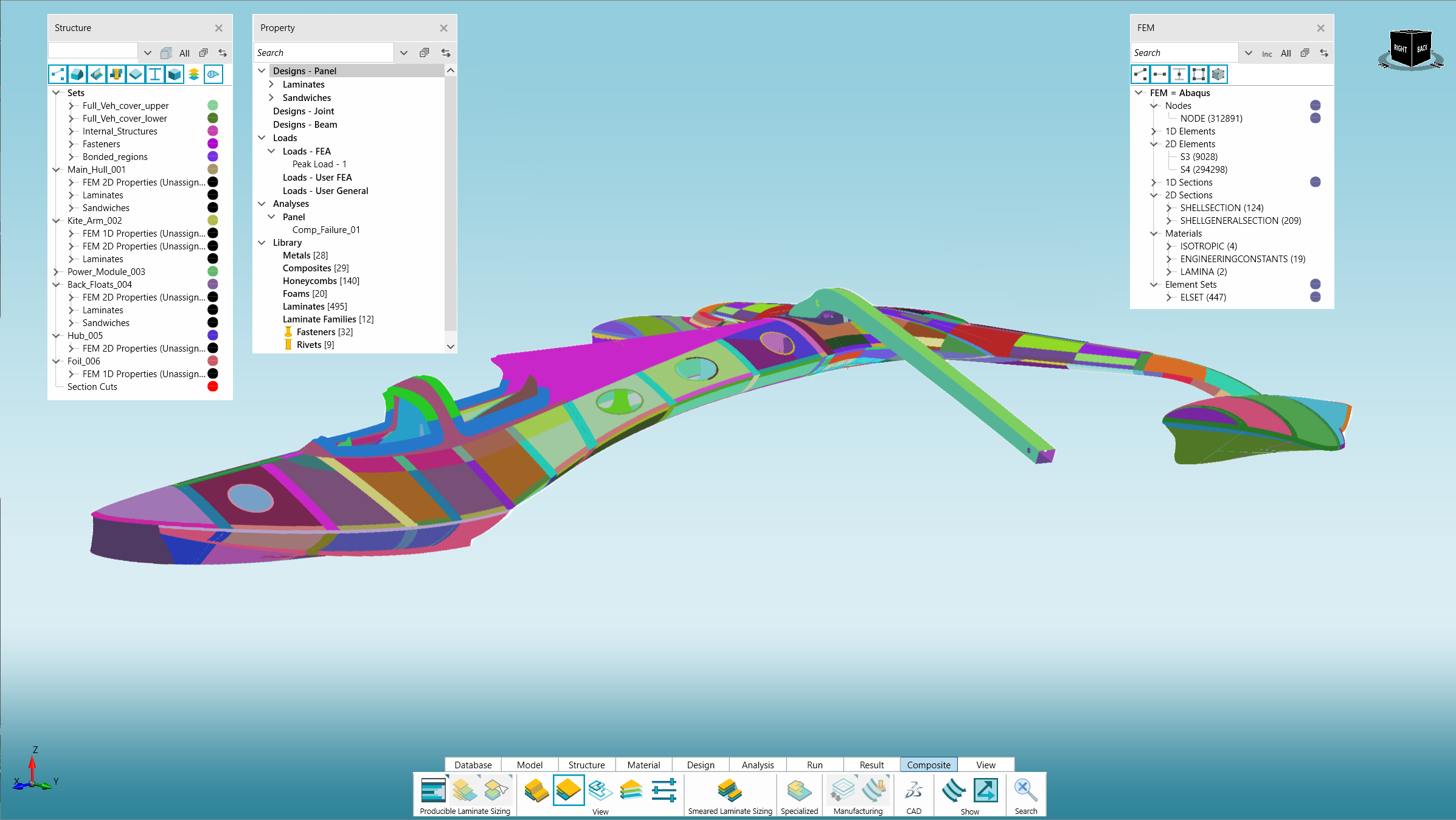

HyperX software provides a complete CAE interface with model-centric user interaction. Drag and drop data assignment makes it very easy to perform what if design studies. Input and computed data is readily seen on the model and in watch window tables for easy inspection.

A Few of our Customers

A Few of our Customers

HyperX in Action

The SP80 team is attempting to break the world sailing speed record by achieving 80 knots solely with wind power. HyperX software and Collier Aerospace engineering expertise was used to design, optimize, and analysis certify the SP80’s core sandwich panels and carbon fiber composite laminates. HyperX enabled the aerospace-like vehicle’s high-performance strength and lightweight.

“The SP80 team was extremely impressed with the new HyperX software and the engineering expertise that we received from Collier Aerospace”, Xavier Lepercq

Says Xavier, SP80 cofounder and technical manager, “The HyperX software was able to size an extremely complex structure and evaluate several different load cases very quickly. We really relied on Collier Aerospace’s engineering judgement and experience to help us make smart decisions. We look forward to collaborating with the Collier Aerospace team on future structural projects.”

Xavier Lepercq

Co-founder – Technical Manager SP80 Team

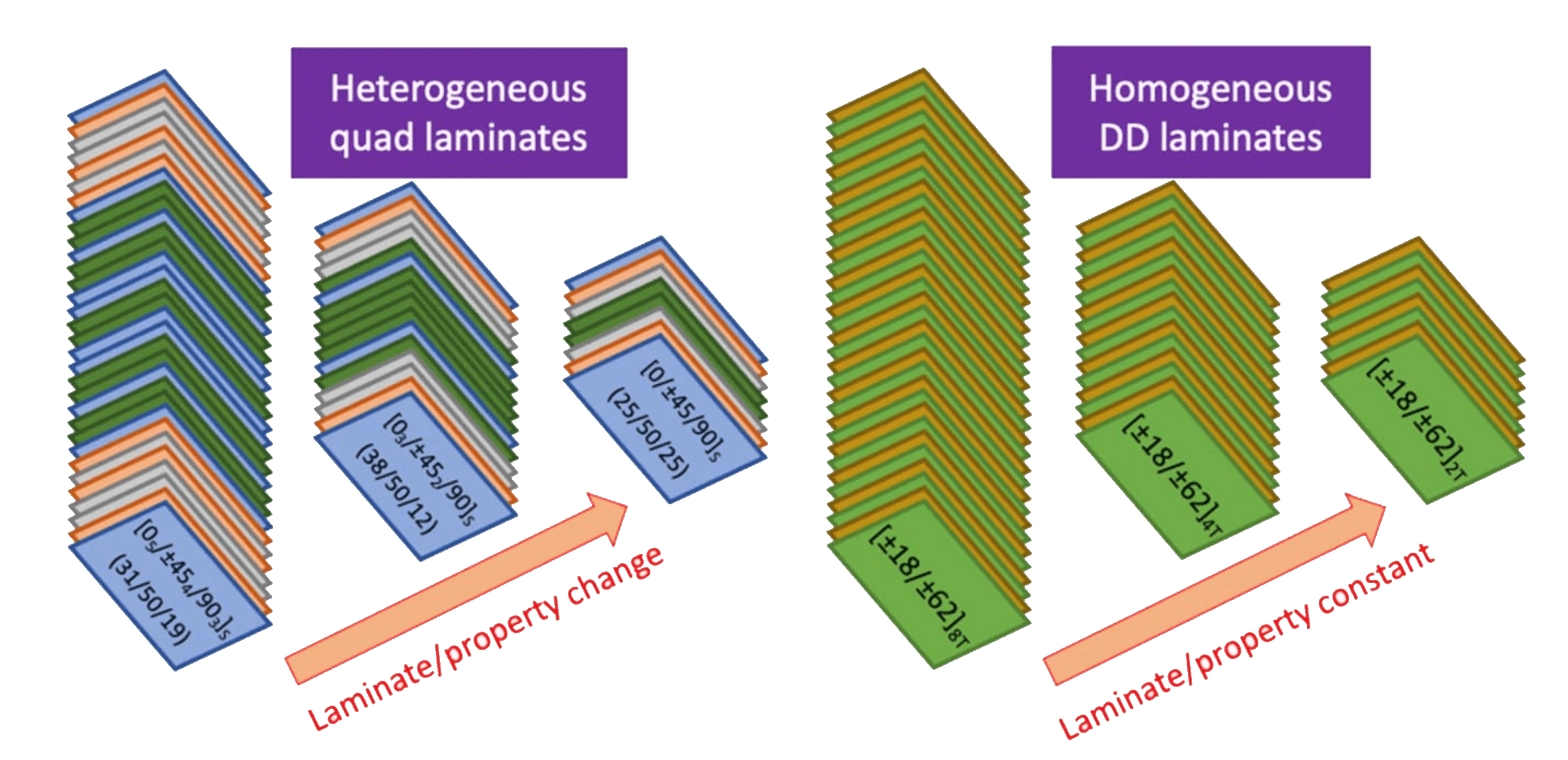

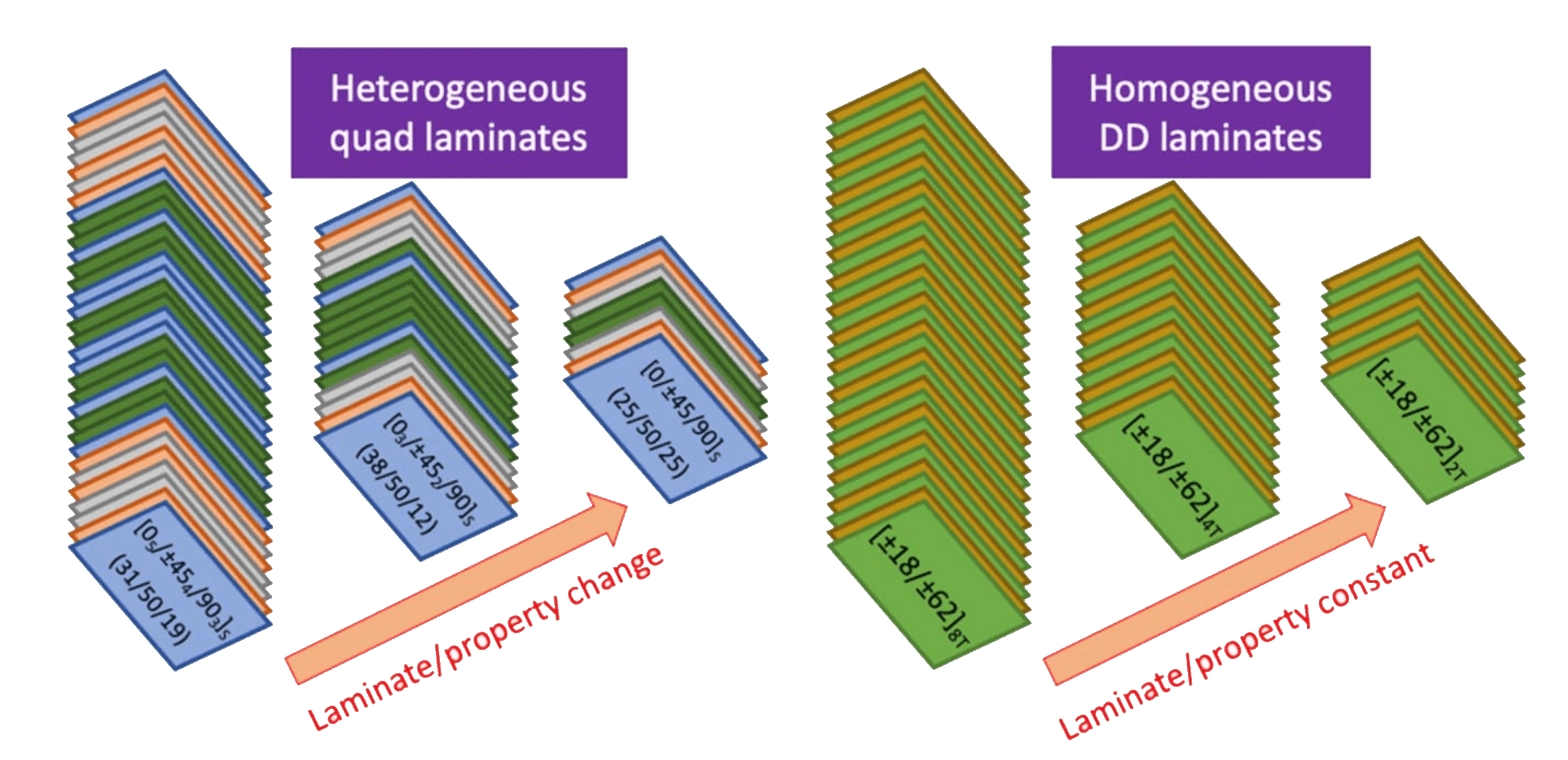

Featured New Capability – Double Double Laminates

A newly discovered approach for designing composite laminates, referred to as the Double Double (DD), was published by Professor Stephen Tsai in October 2021. The DD is a specific type of laminate family based on the repetition of two pairs of angle-plies in the form of [± Φ / ± Ψ], where Φ and Ψ are laminate orientations from 0° to 90°, such as 20°/70°, or 15°/65°. The 4-ply sub-laminate is always the same across a surface, inherently ensuring that DD laminates are homogenous – i.e. their properties remain the same even when the laminate thickness changes as plies are dropped. This makes tapering solutions simpler than the traditional Quad (0/45/90) approach, and similar to what is done on metal parts.

HyperX software automates the creation of DD laminate families and will even determine the optimum [± Φ / ± Ψ] angles to meet your structure’s required stiffness and strength. This ability to optimize DD laminates was presented at the HyperX 2023 Users Conference held at NASA Langley Research Center and at the 2023 American Society of Composites (ASC) Conference in Boston.

Any HyperX feature that is traditionally used with Quad [0, ±45, 90] laminates can also be used with DD [± Φ / ± Ψ] laminate families. This includes structural sizing for solid laminates, sandwich facesheets, and as skins and stringers of stiffened panels. The new stiffener specific laminate family capabilities that have been recently implemented for Quad laminates also apply to DD laminates.

Also of particular note, HyperX provides a laminate trade study tool in which each candidate laminate family is assessed for structure weight and resulting producibility. These results are plotted on a pareto frontier per laminate family, allowing you to determine the optimum ply [± Φ / ± Ψ] angles that reflect your program’s priorities. If so inclined, you can also compare DD results to the optimum traditional Quad layups.

Laminate optimization in HyperX also includes aerospace manufacturing constraints. These constraints ensure designs are manufacturable. This includes: minimizing ply drops across panel boundaries and reducing the number of plies and process steps. As with Quads, when DD laminates are sequenced into part-level plies, the Ply drop/add ramp rate limits are met during the optimization. Typically, in aircraft design the limit is 20 to 1, but the user can select custom values.

As with Quad laminates, the optimum DD laminates are updated in the FEM and in the CAD. HyperX generated CAD panel and beam entities including Quad and DD laminates can be exported as STP, IGES, .JT formats to update fully featured design Catia/3DX/NX CAD data or to import into Hypermesh/FEMAP FEM preprocessors for meshing.

The software is licensed on a subscription basis, either for a single computer or as a floating server license.

Contact us directly for any question you may have. We suggest as a first step to schedule a live demo with one of our engineers.